What you need to know about refrigerant flow

The Thermal Expansion Valve (TXV) is an important piece of equipment in the HVAC industry. The valve is used to control the amount of refrigerant released to the evaporator section. In this way it controls the difference between superheat and the current refrigerant temperature at the evaporator outlet. Therefore, This in turn keeps its saturation temperature at the current evaporating pressure stable. The Thermal Expansion Valve function is the control the flow of refrigerant into the evaporator in response to the cooling load. Additionally, TXV’s measure the superheat at the outlet and react to this by increasing or decreasing the amount of refrigerant flowing into the evaporator to try and maintain a constant superheat.

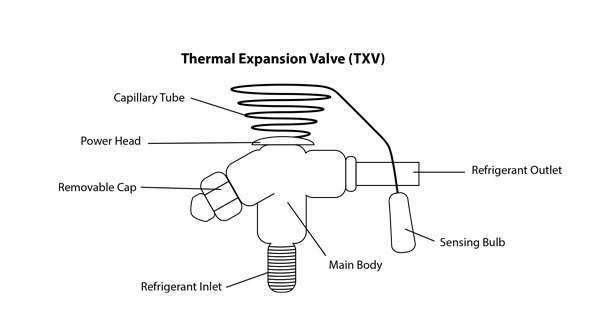

- The TXV Expansion valves reside between the evaporator and condenser in the refrigeration cycle. With the main body made from brass the TXV includes both and inlet and outlet valve. The inlet is located at the bottom while a refrigerator outlet is on the side. On the adjacent side is a removable cap where the superheat is adjustable. Other components include a Power Head, Capillary tube and a Sensing Bulb usually made from stainless steel.

- The coil senses the superheat when stretched out and the bulb sits at the exit of the evaporator. The purpose of this is to ensure that the refrigerant is boiling off and this will leave the evaporator as a slightly superheated vapor and prevent liquid refrigerant entering the compressor. In order to prevent damage or even destroy the device liquids cannot be compressed. The bulb contains a separate refrigerant to avoid mixing with the refrigerant in the rest of the system.

Superheat and Pressure

- The superheat boils the refrigerant inside the bulb and as it boils it creates pressure. Afterwards, the pressure travels along the hollow Capillary tube and into the Power Head and the Power Head controls the flow of refrigerant.

- The expansion valve has a removable cartridge placed inside the inlet. This has an orifice, which works with the valve to control the refrigerant. There are different size cartridges depending on the cooling capacity needed and the type of refrigerant being used.

- The refrigerant comes from the condenser and enters the valve body through the inlet. It enters as a high-pressure, medium temperature saturated liquid. Afterwards it passes through the valve body and when it leaves, it exits the valve through the outlet where there is a conversion to a low-pressure, low-temperature vapor/liquid mixture. This influences the pressure-temperature phase and controls the flow of refrigerant as the pin is connected to the diaphragm in the control head.

How the Diaphragm Functions

- The diaphragm is a thin sheet of metal that moves up and down with the pin. Underneath the diaphragm is a spring that can be adjusted to control the superheat. The sensing bulb sits at the outlet of the evaporator. As a result, the cooling load of the evaporator increases the superheat increases at the evaporator outlet. Because the sensing bulb is in direct contact with the pipe of the evaporator outlet, the thermal energy transfers and causes the refrigerant inside the sensing bulb to expand and boil.

- As the refrigerant expands and boils it causes the pressure inside to increase. This pressure increases and makes its way through the capillary tube and travels to the chamber above the diaphragm. Afterwards, As the pressure increases it pushes down on the diaphragm and this pushes down on the pin. The pin controls how much refrigerant flows through an orifice assembly inside of the valve. The pin being pushed down on the stop is what opens the valve. Pushing down the stopper increases the refrigerant flow. As the cooling load increases on the evaporator, the superheat increases at the outlet.

- The sensing bulb at the outlet detects this and the refrigerant inside boils causing an increase in pressure along the capillary tube. This pressure pushes the diaphragm down which pushes the pin down which opens the valve and lets more refrigerant flow. As more refrigerant flows the superheat decreases so the pressure in the sensing bulb and capillary tube decreases which means there is less pressure pushing the diaphragm down. The spring then pushes the diaphragm back up which causes the pin to move up and as the pin rises the spring-loaded stopper begins to close the orifice which reduces the amount of refrigerant that can flow.

Conclusion

The valve repeats constantly and stabilizes the valve to ensure the correct amount of refrigerant can flow. Finally, The technician can adjust the amount of superheat by turning the adjuster left or right. This changes the sensitivity of the device and therefore allows you to tune the expansion valve and adjust the superheat.