All about packaged units in air conditioning

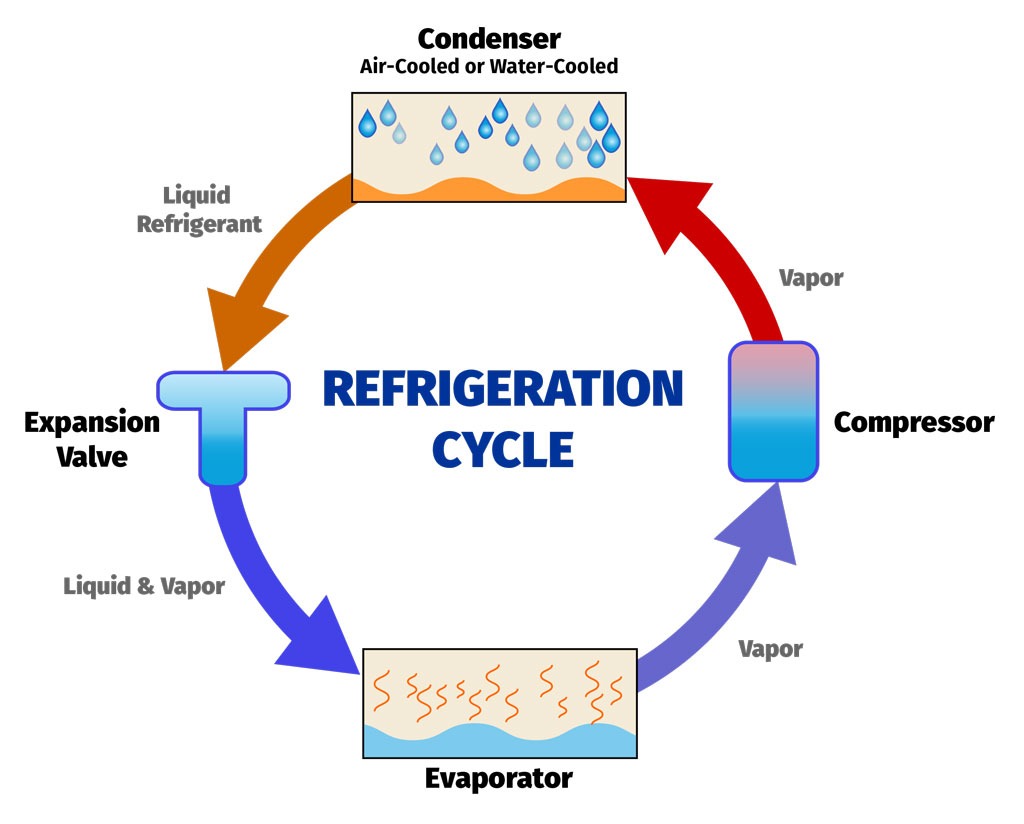

Since the invention of the air conditioner in 1902, engineers have developed various ways of handling the HVAC process. The evaporator and condenser sections are the two major components of Heating, Ventilation and Air Conditioning (HVAC). This is the case as it applies to Direct Expansion (DX) type systems. At the same time, the indoor […]

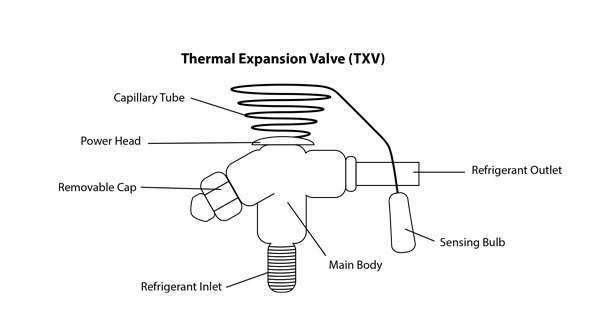

The Thermal Expansion Valve (TXV) Explained

What you need to know about refrigerant flow The Thermal Expansion Valve (TXV) is an important piece of equipment in the HVAC industry. The valve is used to control the amount of refrigerant released to the evaporator section. In this way it controls the difference between superheat and the current refrigerant temperature at the evaporator […]

Commercial vs Residential HVAC Units

Learn the similarities and differences between commercial and residential units Commercial and Residential HVAC units share many similarities but contain many differences as well. While some HVAC manufacturing companies produce units for both markets, others specialize in one or the other. The biggest differences have to do with size, and also whether the unit is […]

Business Owners Guide to Commercial HVAC

When business owners are in need of a new or replacement HVAC system, there may be many questions that arise. First and probably most importantly is the cost. However, cost not only pertains to the price of the equipment, but to the installation cost as well. Equipment cost will vary from one brand to another and […]

Dedicated Outside Air Systems (DOAS)

The late sixties, early seventies ushered a new era into many facets of our lives. The rising cost of oil and uncertainty of supply made it necessary to evaluate what we had taken for granted for many years. The October of 1973 Arab oil embargo sent oil prices rocketing while shortening oil supplies. This caused […]

Hotel HVAC Solutions

Many hotels and other high-rise buildings can develop indoor humidity issues causing high moisture levels. As a result, these problems can lead to damage to the building or discomfort to their guests without having the proper DOAS system into place. It is critical for business designers to implement cost-effective strategies to ensure their buildings are […]